Hello again.

I kind of forgot about this blog after last October. Its now been over a year since my last post. I plan to fix that in the coming weeks. Since that last post I have gone to Herman’s 2018 and Herman’s 2019 Summer and Fall events and acquired many machines.

On to that burning question about the mystery machine that I left on a cliffhanger.

That was a 1925 Remington Electric. Very rare only 11 known to exist (currently).

Since then I have acquired many more machines. These include

- Smith Premier No 1

- Smith Premier No 3

- Smith Premier No 4

- Smith Premier No 10 (yes another one)

- Fox 3

- Fox 4

- Fox 25

- Hammond 2

- Remington Standard 2

- Oliver 3 (x2)

- Bar-Lock 6

- Victor 2

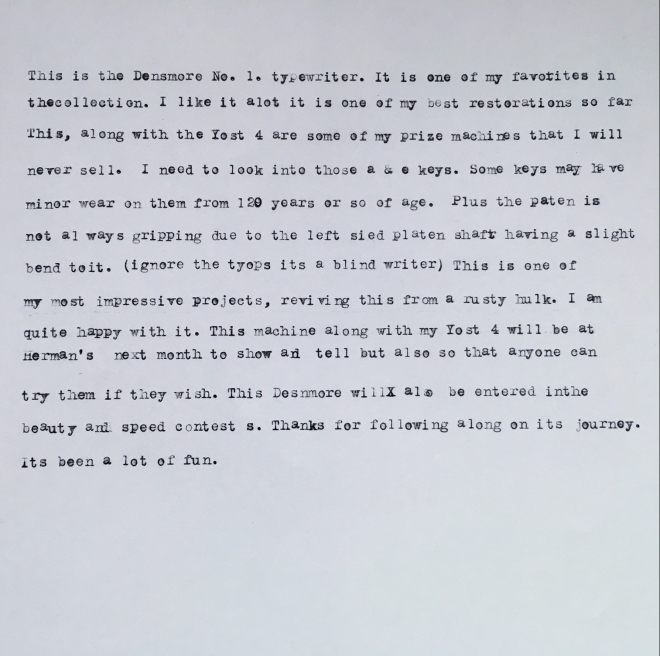

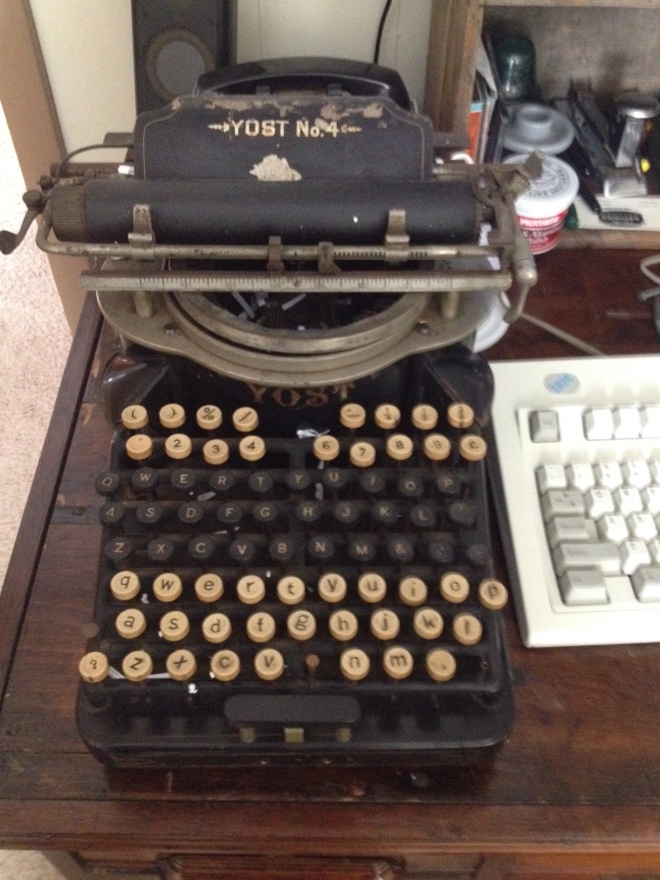

- Densmore 4

However, when I buy all these new machines sometimes machines have to leave the collection to make room for and to finance the new arrivals.

- Smith Premier No 5

- LC Smith 5

- 1926 Remington 12

- LC Smith Super Speed

- Royal KHM

I also have a new website devoted entirely to the Densmore Typewriter

That’s all for now.